Advanced Robotics for Material Handling

Intelligent Material Handling with Advanced Robotic Systems

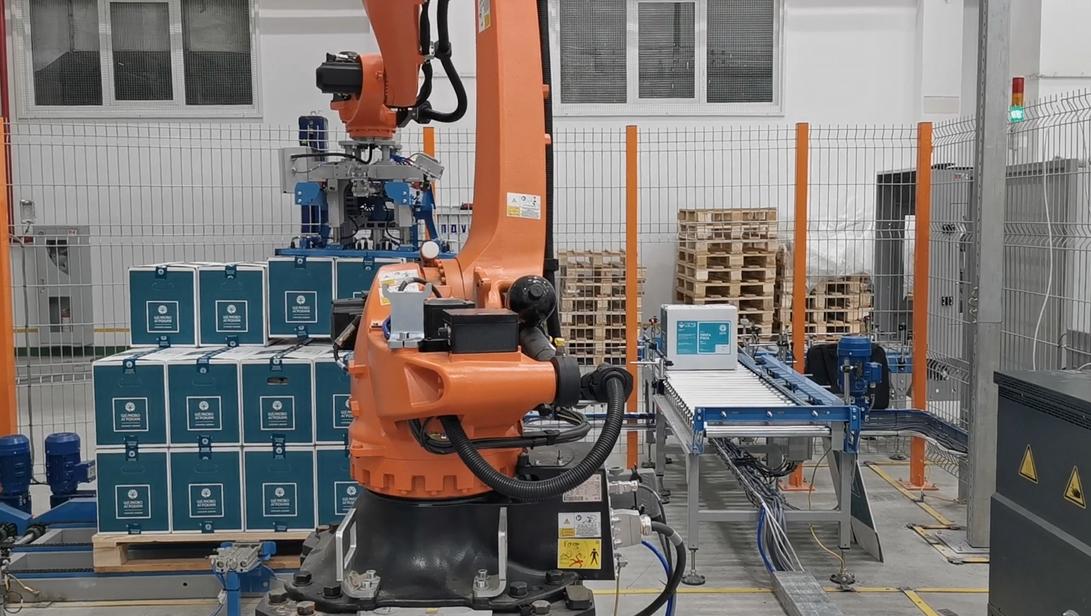

Robotics technology in warehousing and manufacturing encompasses a range of automated systems designed to enhance efficiency, accuracy, and productivity. These systems include robotic arms, autonomous mobile robots (AMRs), automated guided vehicles (AGVs), and collaborative robots (cobots). Robotics solutions are integral to modern supply chain operations, enabling seamless automation of tasks such as picking, packing, palletizing, and transportation of goods. By leveraging advanced robotics, businesses can streamline operations, reduce labor costs, and improve overall performance.

Technology Benefits

- Increased Efficiency: Robotics automate repetitive and time-consuming tasks, significantly speeding up processes and increasing throughput.

- Enhanced Accuracy: Robots perform tasks with high precision, reducing errors and improving the quality of operations.

- Improved Safety: By handling hazardous or physically demanding tasks, robots enhance workplace safety and reduce the risk of injuries.

- Scalability: Robotic systems can be easily scaled to meet growing operational demands and adapt to changing business needs.

- Cost Savings: Automation reduces labor costs and minimizes downtime, leading to substantial long-term savings.

Considerations

- Initial Investment: Implementing robotics solutions requires a significant upfront investment, but the long-term benefits often justify the cost.

- Integration: Ensuring seamless integration with existing systems and processes is crucial for maximizing the benefits of robotics.

- Maintenance: Regular maintenance and updates are necessary to keep robotic systems running efficiently and prevent downtime.

- Employee Training: Staff will need training to effectively operate, manage, and maintain robotic systems.

- Space Requirements: Adequate space must be allocated for the installation and operation of robotic systems.

Available Technologies

- Autonomous Mobile Robots (AMRs): Navigate warehouse floors autonomously to transport goods, enhancing flexibility and efficiency.

- Automated Guided Vehicles (AGVs): Follow predetermined paths to move products within a facility, improving transportation efficiency.

- Collaborative Robots (Cobots): Work alongside human operators, enhancing productivity while ensuring safety.

- Robotic Picking Systems: Automate the picking process, increasing speed and accuracy.

- Robotic Palletizers: Stack products onto pallets with precision and consistency, reducing manual labor.

- Automated Storage and Retrieval Systems (AS/RS): Integrate with robotics to automate the storage and retrieval of items, optimizing space and efficiency.

BoxLogix offers state-of-the-art robotics solutions designed to transform your warehouse and manufacturing operations. Our expertise as a systems integrator ensures seamless integration of advanced robotic technologies with your existing infrastructure, maximizing efficiency, accuracy, and scalability. Contact us today to discover how our innovative robotics solutions can enhance your material handling processes and drive your business forward.