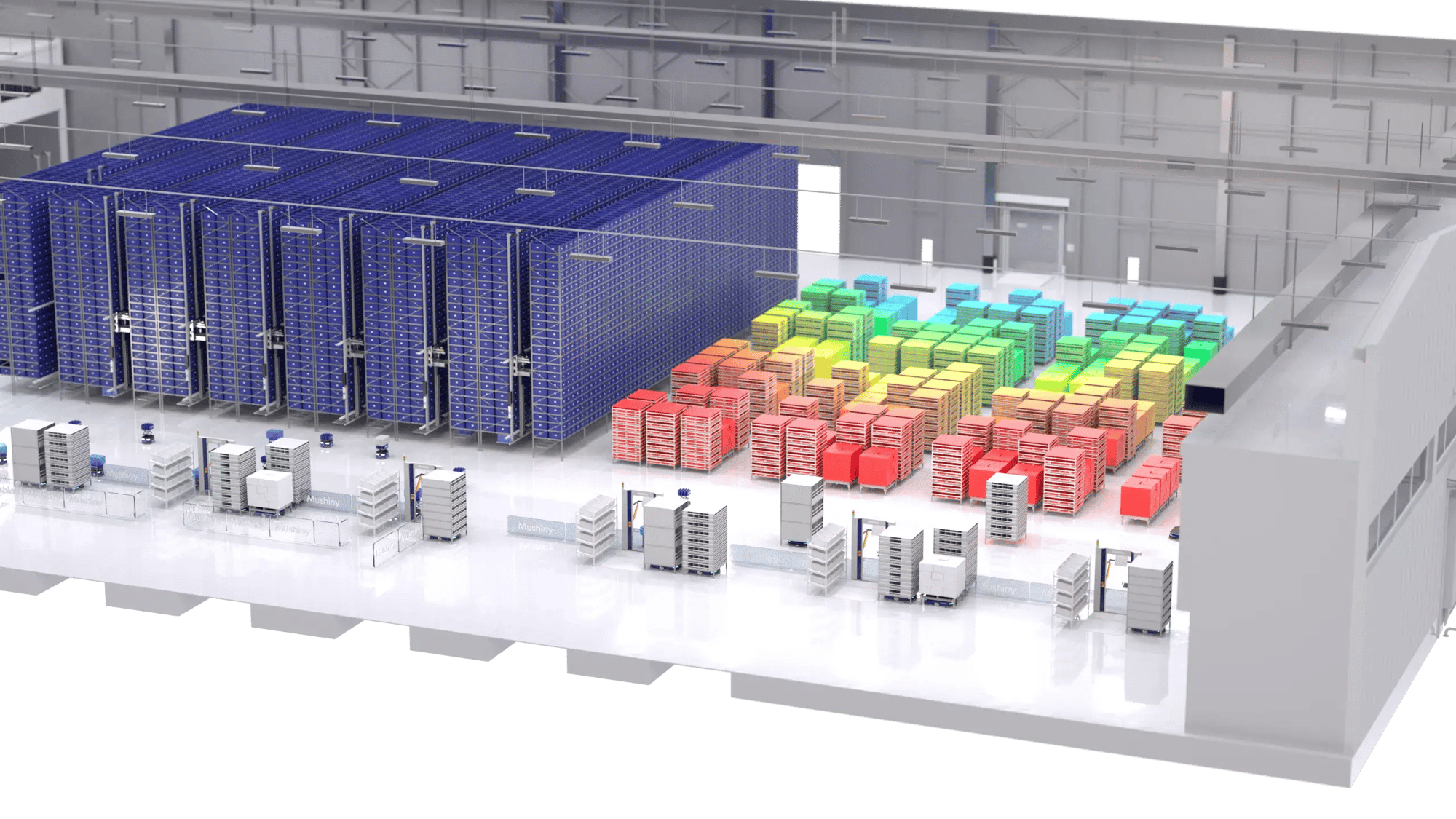

Automated Goods-to-Person Workflows

Intelligent Goods-to-Person Fulfillment

Goods-to-Person (GTP) systems are advanced material handling solutions that bring products directly to the operator, rather than requiring the operator to travel to the product. Utilizing a combination of automated storage and retrieval systems (AS/RS), conveyor systems, and robotics, GTP systems optimize the picking process by reducing travel time, increasing picking speed, and improving accuracy. These systems are ideal for high-density storage environments and operations with a high volume of small-item picks.

Technology Benefits

- Increased Productivity: By bringing goods directly to the operator, GTP systems significantly reduce the time spent walking and searching for items, boosting overall picking efficiency.

- Enhanced Accuracy: Automated systems and precise inventory management reduce errors, ensuring that the correct items are picked and delivered.

- Improved Ergonomics: GTP systems minimize the physical strain on workers by eliminating the need for excessive walking, bending, and reaching.

- Scalability: These systems can be easily scaled to accommodate growth in order volume or changes in product range.

- Cost Savings: Reduced labor costs and improved operational efficiency result in significant cost savings over time.

Considerations

- Initial Investment: The implementation of GTP systems can require a substantial initial investment, but the long-term benefits often justify the cost.

- System Integration: Ensuring compatibility with existing warehouse management systems (WMS) and other technologies is crucial for seamless operation.

- Maintenance: Regular maintenance is necessary to ensure the reliability and performance of GTP systems.

- Employee Training: Operators and maintenance staff will need training to effectively use and manage the new technology.

- Space Requirements: Adequate space must be allocated for the installation and operation of GTP systems.

Available Technologies

- Automated Storage and Retrieval Systems (AS/RS): Central to GTP solutions, AS/RS units automatically store and retrieve items, delivering them to the operator.

- Shuttle Systems: Use high-speed shuttles to move products within the storage area, providing quick and efficient retrieval.

- Vertical Lift Modules (VLMs): Automated vertical storage systems that bring items to the operator at an ergonomic height, optimizing space and picking efficiency.

- Robotic Picking Systems: Utilize robots to pick items from shelves and deliver them to the operator, further enhancing speed and accuracy.

- Conveyor Systems: Integrated conveyors transport items from storage areas to picking stations, streamlining the workflow.

BoxLogix offers state-of-the-art Goods-to-Person systems designed to transform your picking and material handling processes. Our expertise as a systems integrator ensures seamless integration of GTP technologies with your existing operations, maximizing efficiency, accuracy, and scalability. Contact us today to discover how our innovative Goods-to-Person solutions can enhance your warehouse or distribution center's performance and drive your business forward.