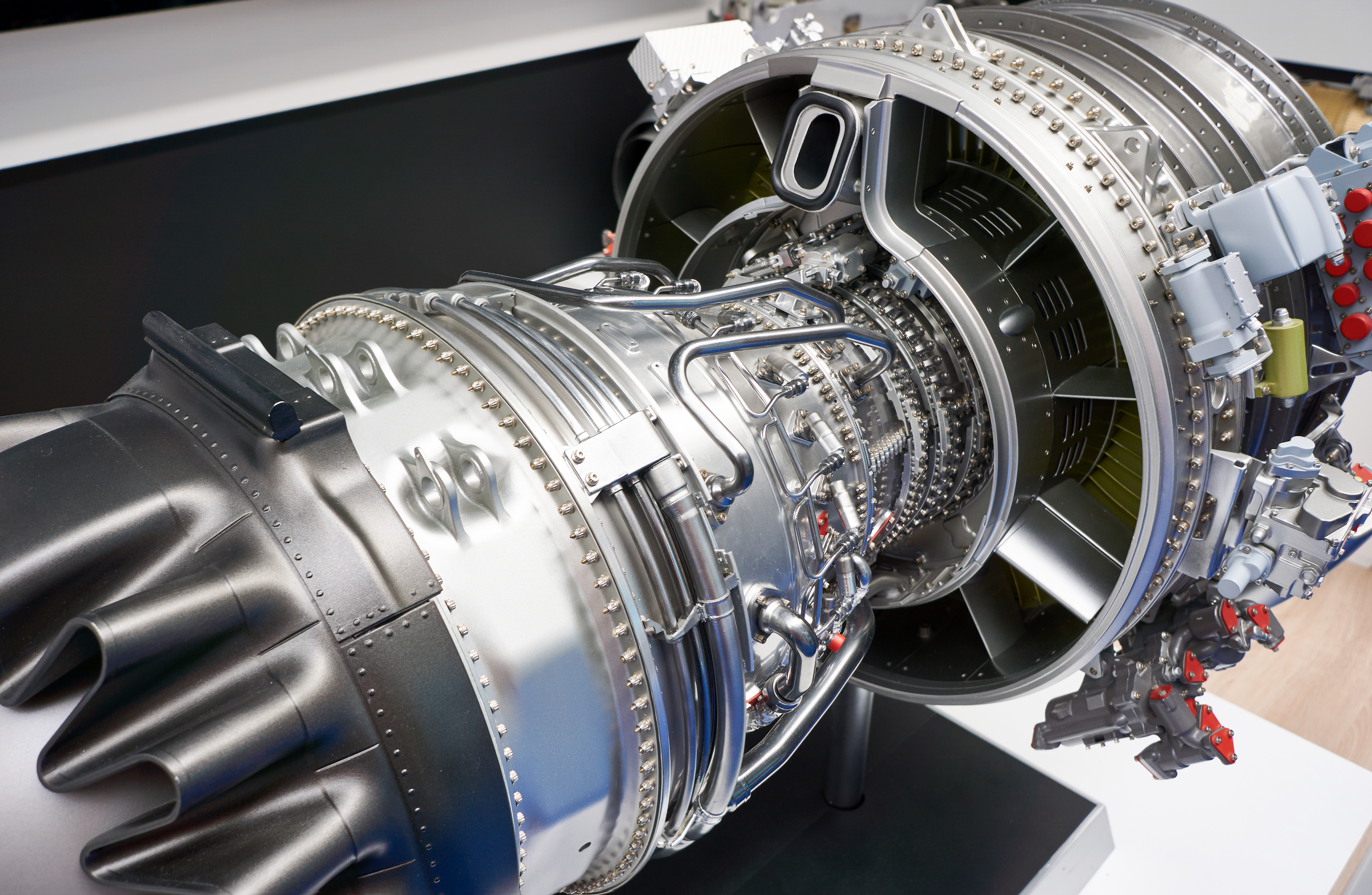

Smart Automation Solutions for Aerospace & Defense Operations

BoxLogix delivers precision automation built for the complex demands of aerospace and defense manufacturing. Our systems streamline the movement of sensitive components, assemblies, and finished parts across production zones while supporting compliance and quality control. From cleanroom handling to packaging high-value components, we help reduce labor, improve traceability, and boost accuracy with scalable solutions engineered for secure and high-spec environments.

- AGVs & AMRs for Component/Pallet Transport

- Robotic Palletizing/Depalletizing Solutions

- VLMs for Component Storage

- AS/RS Systems for Dense Pallet Storage

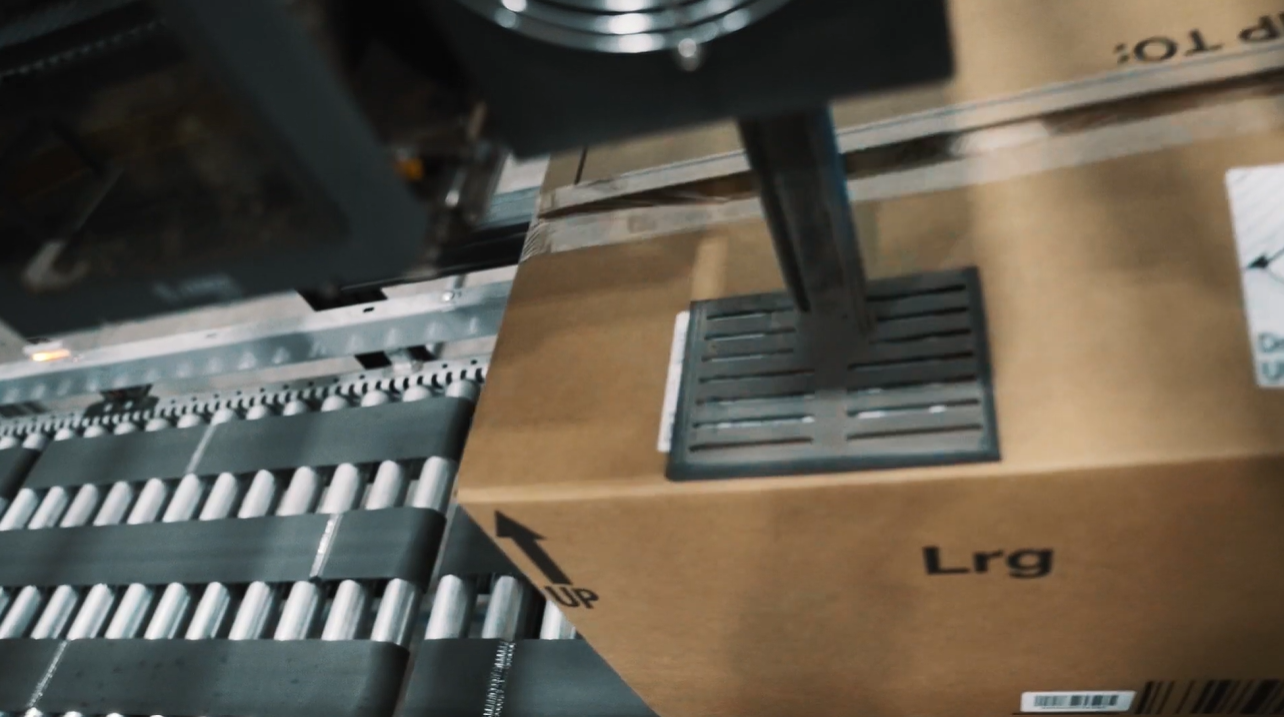

- Automated Labeling Systems

.png)

.png)

.png?width=2001&height=858&name=BL%20Website%20(1).png)

.png)