Goods-to-Person Solutions Available

- Robotic Mobile G2P (AMRs/AGVs)

- Shelf-to-Person Strategies

- Horizontal Carousel Systems

- Put-to-Light / Pick-to-Light Integration

- Mini-Load Cranes

- Vertical Lift Modules (VLMs)

Goods-to-Person (G2P) automation systems deliver items directly to operators, reducing manual travel, increasing picking speed, and improving overall warehouse efficiency.

Get in TouchGoods-to-Person (G2P) technology is beneficial because it eliminates the wasted time and labor of workers walking to pick items. Instead, automation brings products directly to operators, which streamlines order fulfillment, increases throughput, improves accuracy, and reduces fatigue. By centralizing picking stations and automating product retrieval, companies can maximize storage density, optimize labor efficiency, and scale operations more easily to meet demand.

Peak lines/hr, presentations/min per station, # of concurrent orders.

# of workstations required, buffers/WIP between storage and stations.

Lift counts, aisle density, robot fleet sizing, redundancy.

System type: shuttle, miniload, cube-based AS/RS, AMR/AGV, vertical buffer.

Reach envelopes, height adjustability, pick/put confirmation devices (PTL, screens).

Present-to-person sequencing, 1:1 vs. 1:many put walls, trash/void fill/pack adjacency.

Footprint, mezzanines, egress, seismic/fire code (sprinklers in racks, in-rack detection).

Let BoxLogix assess your operation to uncover opportunities to streamline processes and improve efficiency. Our team uses real data from your facility to build a clear picture of how automation can deliver the most impact. With decades of experience, we tailor every assessment to your unique goals, helping you plan the right system for today while preparing for tomorrow.

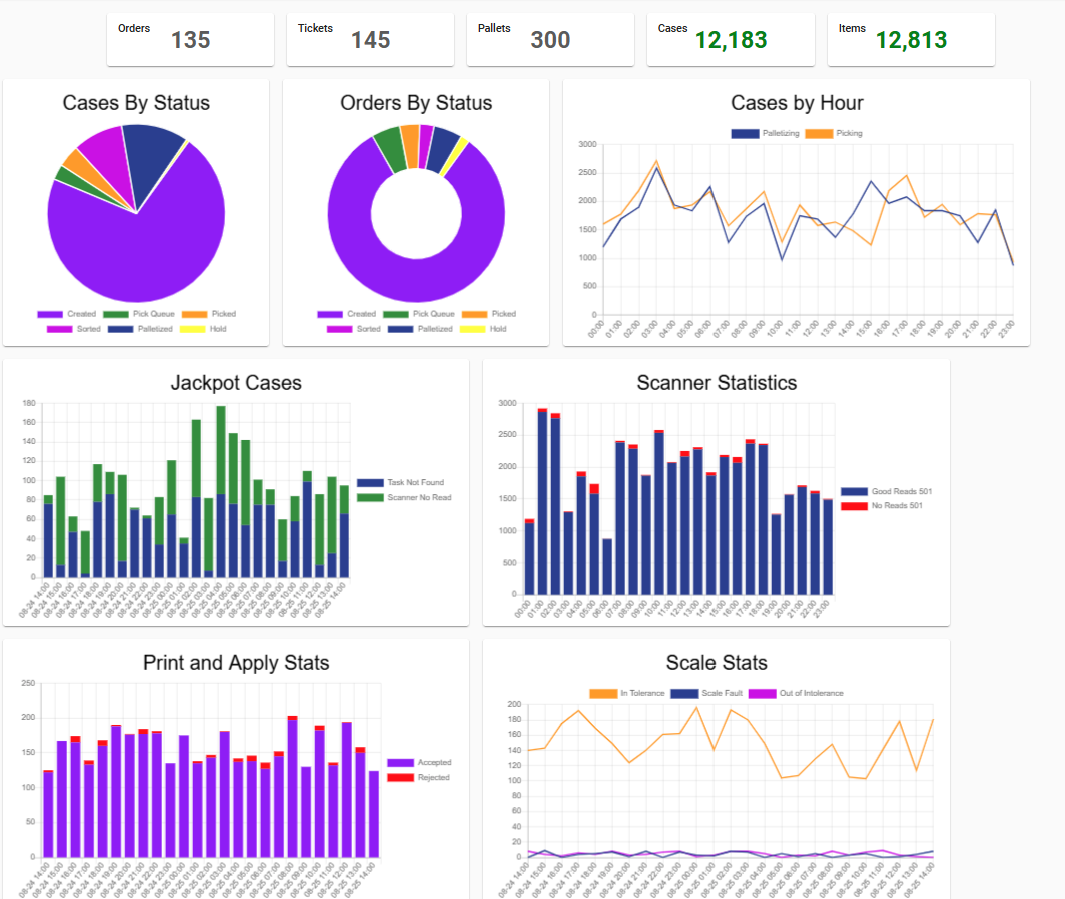

Logix is the cutting-edge warehouse control system built to unify your operation. It connects conveyors, shuttles, robotics, and AS/RS into one streamlined platform—giving you real-time visibility and reliable control. Designed in-house by BoxLogix, Logix is flexible, operator-friendly, and proven to keep automation running at peak performance.

Read More on Logix

.png?width=2001&height=858&name=BL%20Website%20(1).png)

Our Automation Assessment process is designed to identify inefficiencies and unlock opportunities in your warehouse or distribution center. Through detailed analysis and simulation, we help you right-size automation and reduce footprint while maximizing ROI.

Our team is committed to your long-term success with proactive maintenance, expert troubleshooting, and 24/7 support—ensuring your systems run reliably and efficiently every day.

.png)

Our team can help you explore automation strategies that improve efficiency, reduce labor, and scale with your operations.

Fill out the form to schedule a discovery call, ask a question, or request a solution overview.

Thank you! We’ll be in touch soon.