Smart Automation Solutions for High-Volume Order Fulfillment

BoxLogix designs automation systems that optimize receiving, storage, picking, and shipping. Our solutions reduce labor, boost accuracy, and scale with demand—whether handling parcels or pallets. We integrate robotics, conveyance, and smart controls to keep your operations efficient and flexible.

- Goods-to-Person Systems

- Conveyance & Sortation

- Mobile Robotics (AMRs & AGVs)

- WCS Integration (Logix)

- Returns Optimization

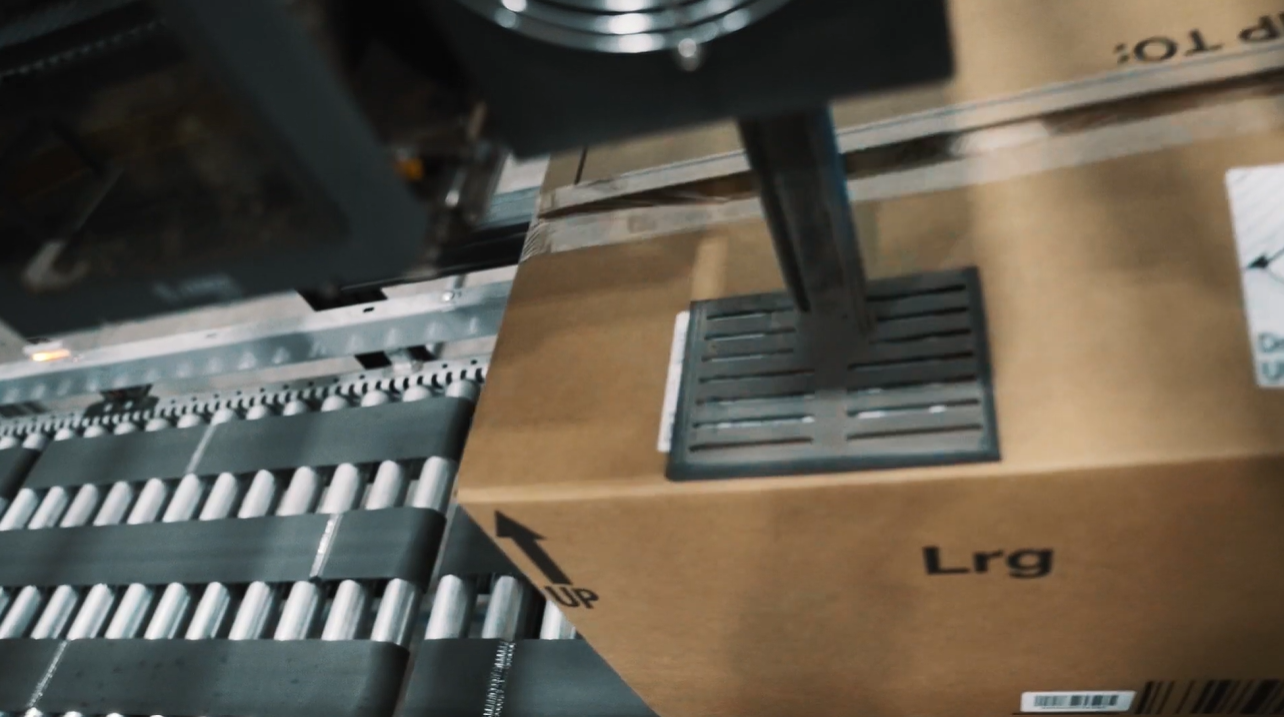

- Print & Apply Systems

.png)

.png)

.png?width=2001&height=858&name=BL%20Website%20(1).png)

.png)