Conveyance Solutions Available

- Vertical conveyor

- Belt conveyor

- Accumulation conveyor

- Empty corrugate conveyor

- Chain Conveyor

- Pallet Conveyor

- Sortation Systems

- Roller Conveyor

Streamline your operations with efficient, scalable conveyor systems designed to move product faster, safer, and smarter.

Get in TouchConveyor systems are a vital component of modern material handling operations, designed to transport goods and materials efficiently across warehouses, distribution centers, and manufacturing facilities. These systems use various types of mechanical devices to move items along a predetermined path, ensuring smooth and reliable material flow. Conveyor systems can be tailored to meet specific operational requirements, providing solutions for sorting, merging, and accumulating products. They play a crucial role in streamlining processes, reducing manual labor, and enhancing productivity. <br>

Peak vs. average rate (cases/min), accumulation strategy, merge/divert logic, singulation/gapping, recirculation paths.

Dimensions/weight of handling units, center of gravity, surface friction, package rigidity, barcode/label orientation requirements.

Footprint, elevations and transitions (inclines/declines), minimum curve radii, clearances, maintenance access, egress paths.

Printers/labelers, scanners, weigh scales, wrappers, sorters, palletizers, AS/RS, AMRs—hand-off points and buffer zones.

PLC platform, fieldbus (EtherNet/IP/Profinet), I/O count, device addressing, safety PLC, WCS/WMS/ERP handshakes (SKU, routes, exceptions), OEE/data logging.

Photoeyes placement, jam detection, skew/stop control, barcode/vision read rates, weight/size checks, reject lanes and exception handling.

Let BoxLogix assess your operation to uncover opportunities to streamline processes and improve efficiency. Our team uses real data from your facility to build a clear picture of how automation can deliver the most impact. With decades of experience, we tailor every assessment to your unique goals, helping you plan the right system for today while preparing for tomorrow.

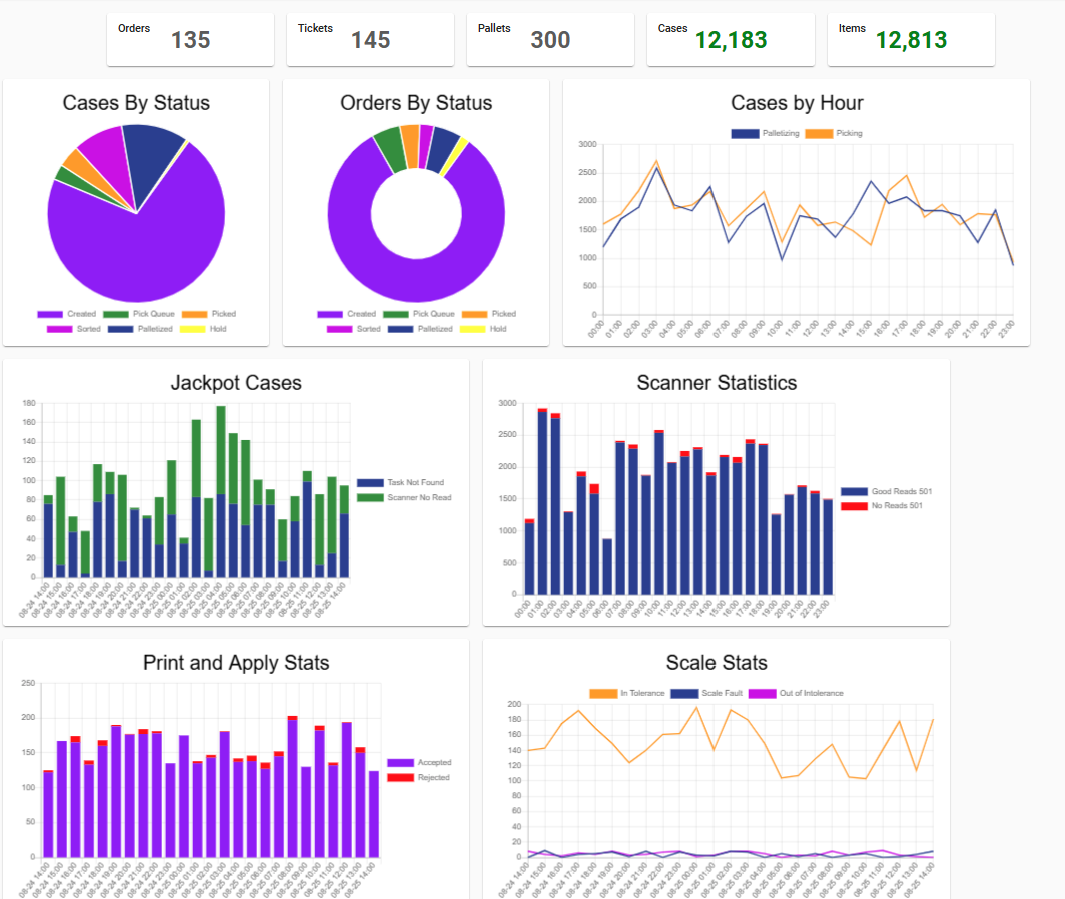

Logix is the cutting-edge warehouse control system built to unify your operation. It connects conveyors, shuttles, robotics, and AS/RS into one streamlined platform—giving you real-time visibility and reliable control. Designed in-house by BoxLogix, Logix is flexible, operator-friendly, and proven to keep automation running at peak performance.

Read More on Logix

.png?width=2001&height=858&name=BL%20Website%20(1).png)

Our Automation Assessment process is designed to identify inefficiencies and unlock opportunities in your warehouse or distribution center. Through detailed analysis and simulation, we help you right-size automation and reduce footprint while maximizing ROI.

Our team is committed to your long-term success with proactive maintenance, expert troubleshooting, and 24/7 support—ensuring your systems run reliably and efficiently every day.

.png)

Our team can help you explore automation strategies that improve efficiency, reduce labor, and scale with your operations.

Fill out the form to schedule a discovery call, ask a question, or request a solution overview.

Thank you! We’ll be in touch soon.