Picking Technologies Available

- Pick-to-Light Systems

- Belt conveyor

- Put-to-Light Systems

- Voice Picking

- Goods-to-Person (G2P) Picking

- Robotic Picking

- Pick Modules with Conveyors

From light-directed systems to goods-to-person automation, today’s picking technologies are designed to eliminate wasted steps, improve accuracy, and accelerate fulfillment.

Get in TouchPicking technologies improve order accuracy and speed by guiding operators or automating retrieval, reducing errors and wasted movement. They also optimize labor efficiency, allowing warehouses to handle higher volumes with less strain on staff.

Improved Accuracy – Reduces human error through guided or automated picking processes.

Labor Efficiency – Minimizes walking and manual searching, allowing staff to focus on higher-value tasks.

Enhanced Visibility – Integrates with WMS/WCS for real-time tracking, reporting, and operational insight.

Better Ergonomics – Reduces repetitive strain by presenting items directly or guiding operators efficiently.

Cost Savings – Lowers rework, returns, and labor costs tied to errors and inefficiencies.

Customer Satisfaction – Enables faster, more accurate deliveries that build trust and loyalty.

Lines/order, units/line, % single-line vs multi-line, order cube/weight. Peaks (daily / weekly / seasonal), cut-off times, service levels.

Required UPH/LPH (units/lines per hour) at peak.

Velocity (A/B/C), cube, weight, fragility, temperature/hazmat classes.

Dedicated vs. shared locations; re-slot frequency; slotting rules.

Person-to-Goods (PTG) vs. Goods-to-Person (GTP.)

Pick-to-Light / Put-to-Light, voice, RF, vision, smart carts, AMR-assisted.

System of record, task ownership (WMS vs. WES/WCS), APIs/queues.

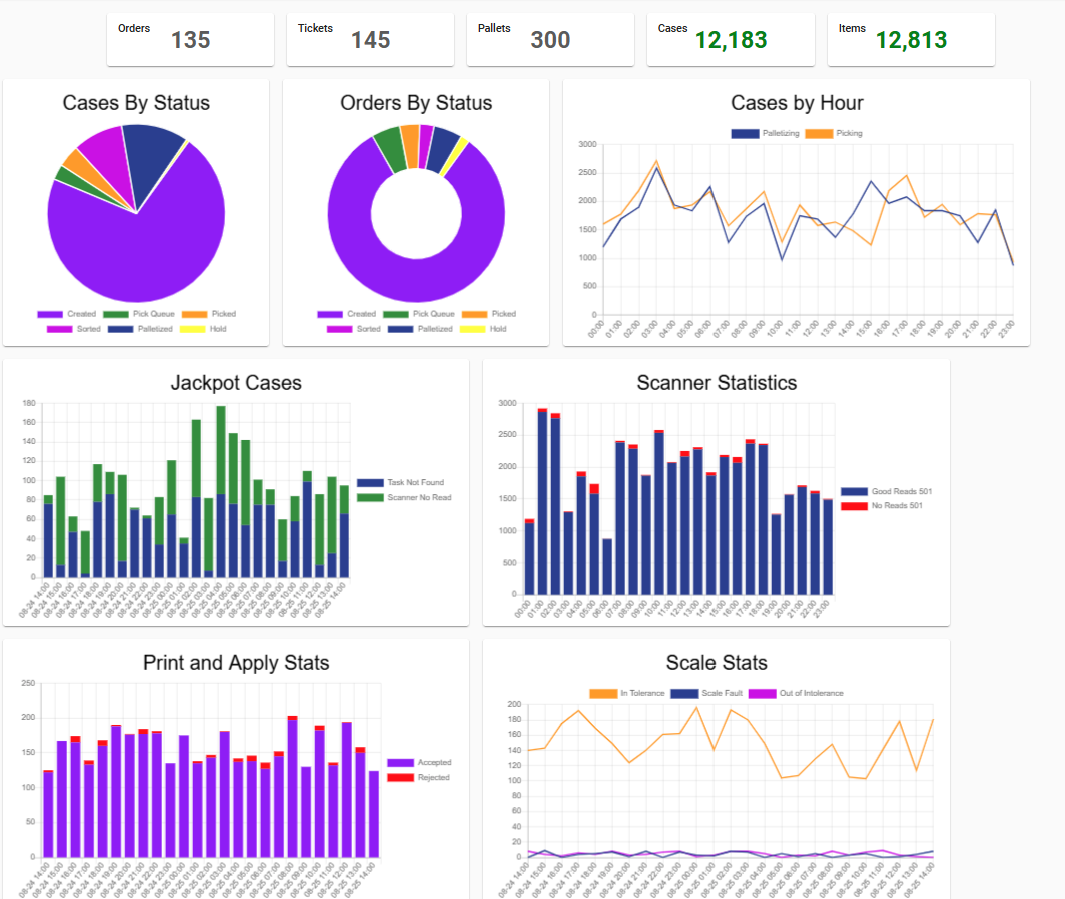

Live: UPH/LPH, pick accuracy, backlog, station utilization, age of work.

Historical: SLA hit rate, labor productivity, rework, root-cause trends.

Let BoxLogix assess your operation to uncover opportunities to streamline processes and improve efficiency. Our team uses real data from your facility to build a clear picture of how automation can deliver the most impact. With decades of experience, we tailor every assessment to your unique goals, helping you plan the right system for today while preparing for tomorrow.

Logix is the cutting-edge warehouse control system built to unify your operation. It connects conveyors, shuttles, robotics, and AS/RS into one streamlined platform—giving you real-time visibility and reliable control. Designed in-house by BoxLogix, Logix is flexible, operator-friendly, and proven to keep automation running at peak performance.

Read More on Logix

.png?width=2001&height=858&name=BL%20Website%20(1).png)

Our Automation Assessment process is designed to identify inefficiencies and unlock opportunities in your warehouse or distribution center. Through detailed analysis and simulation, we help you right-size automation and reduce footprint while maximizing ROI.

Our team is committed to your long-term success with proactive maintenance, expert troubleshooting, and 24/7 support—ensuring your systems run reliably and efficiently every day.

.png)

Our team can help you explore automation strategies that improve efficiency, reduce labor, and scale with your operations.

Fill out the form to schedule a discovery call, ask a question, or request a solution overview.

Thank you! We’ll be in touch soon.