Smart Automation Solutions for Cold Storage Warehousing

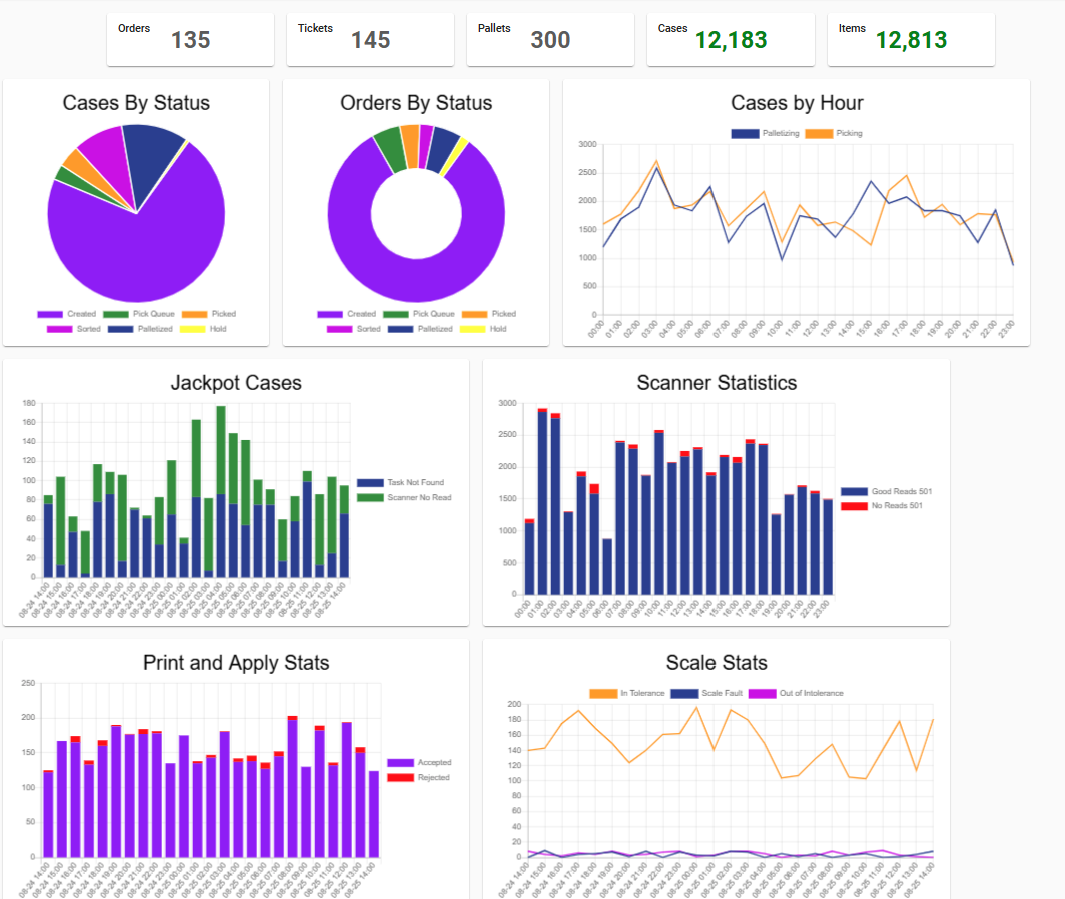

BoxLogix delivers cold storage automation built to thrive in temperature-controlled environments. Our solutions help optimize throughput, storage density, and labor efficiency across frozen and refrigerated zones. Whether managing palletized goods, case picking, or staging for outbound shipments, we design systems that reduce energy loss, improve inventory traceability, and increase uptime in harsh environments. Every system is engineered to support cold chain compliance, reduce footprint, and drive long-term operational savings.

- Pallet Shuttle AS/RS Systems

- AMRs & AGVs

- Palletizing Systems

- Case Picking

- Stretch Wrappers

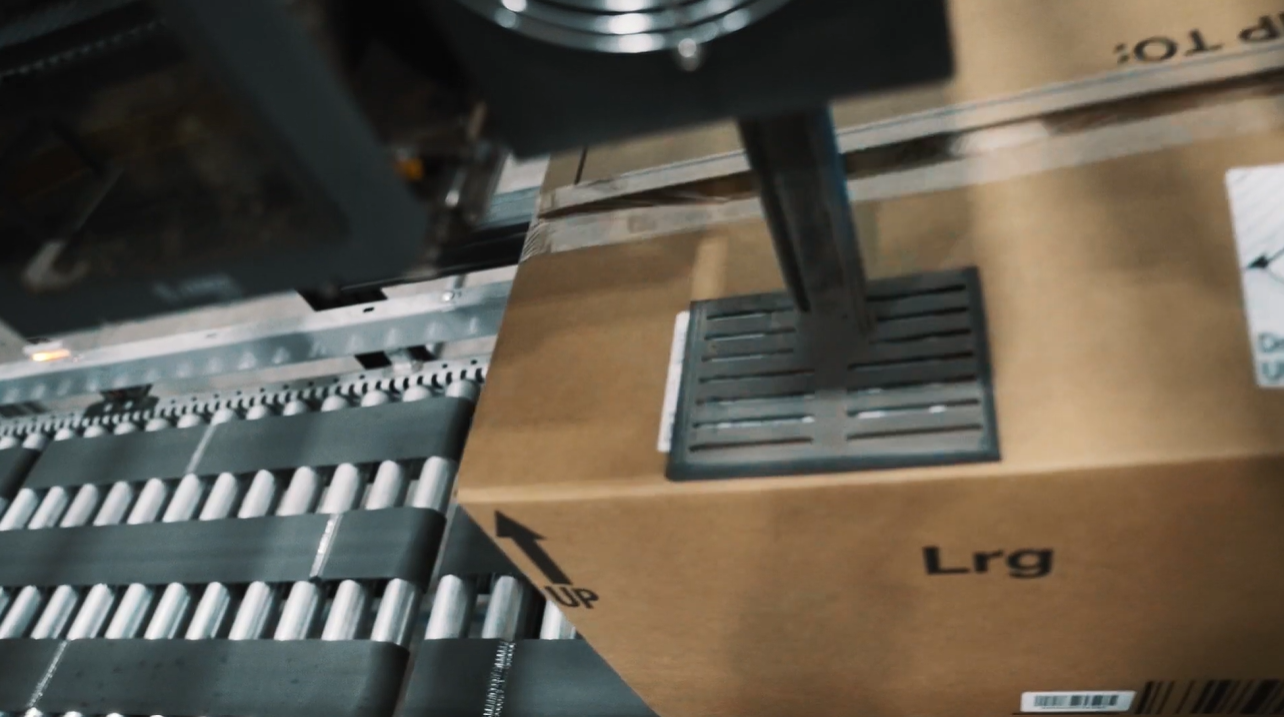

- Automated Labeling Systems

.png)

.png)

.png?width=2001&height=858&name=BL%20Website%20(1).png)

.png)