Smart Automation Solutions for Manufacturing Operations

BoxLogix delivers smart automation tailored to the demands of modern manufacturing. Our systems help streamline intralogistics by automating the flow of parts, subassemblies, and finished goods between production zones. From assembly line support to end-of-line packaging, we optimize material movement, reduce labor, and improve accuracy with scalable solutions designed for tough industrial environments.

- AGVs & AMRs for In-Plant Material Transport

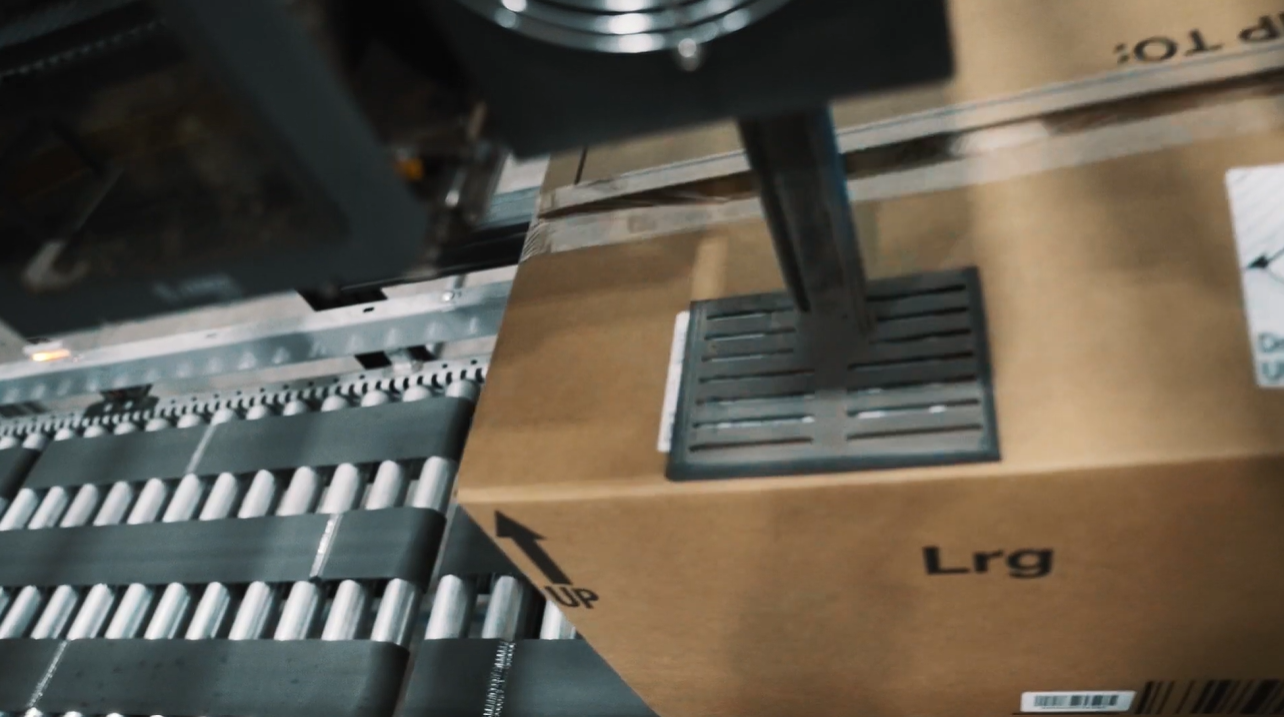

- End-of-Line Palletizing & Packaging Systems

- Conveyor Integration with Workstations & Robotics

- AS/RS Systems for Dense Pallet Storage

- Automated Pallet Wrapping & Labeling

.png)

.png)

.png?width=2001&height=858&name=BL%20Website%20(1).png)

.png)